AMSOIL Performance & Road Tests

| Bypass Filtration Page – Soot Reduction |

Keeping Engines Clean with AMSOIL

Though conventional motor oil quality has improved over the past 30 years, this progress is also offset by emission-reduction strategies, but now variable valve timing (VVT) improves things but creates different requirements for motor oils in combination with GDI, which strangles the engine a little tighter and makes it run hotter.

The average motorist (prior to 2015) has never even heard of variable valve timing and/or GDI, but it’s a critical component in the operation of a vehicle. Almost every vehicle manufacturer has published a bulletin stating that the number one cause of variable-valve-timing system problems is small amounts of residue and sludge. In other words, cleanliness is absolutely essential.

In the old days, the engine’s intake and exhaust valves were set to open and shut at specific points in the four stroke cycle for a set amount of time. With variable valve timing, engines can adjust the timing for when and how long these valves open and shut by relying on a combination of sensors and mechanical systems, many critically located on the camshaft and crankshaft. When these components get gummed-up with sludge or deposits, it can lead to poor performance and costly repair bills.

Because AMSOIL synthetic motor oil resists oxidation and breakdown in high heat, it is less prone to produce the varnish and sludge that damages these critical sensors.

Keeping engines clean by using AMSOIL synthetic motor oils helps them last longer. Cleanliness reduces wear, ring sticking and emissions while helping ensure all these components operate as designed.

| 215 Trucks Maintenance Problems Significantly Reduced thanks to AMSOIL – Jeff Foster Trucking in Duluth. |

Refuse Hauler Fleet – Field Study

| In order to test the performance capabilities of AMSOIL Synthetic 15W-40 Heavy Duty Diesel and Marine Oil (AME), AMSOIL sought a partner with a fleet that operated in truly severe conditions.

The perfect match was found in Duluth, Minn.-based Nordic Waste. |

|---|

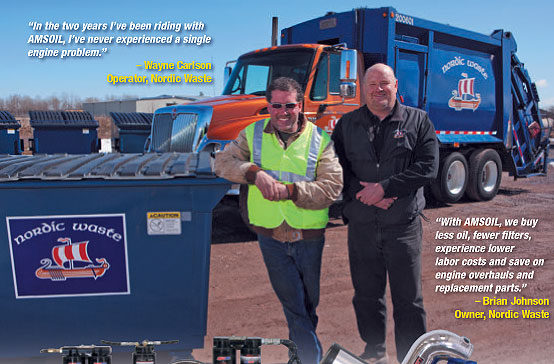

Nordic Waste operates a fleet of 10 International refuse haulers,

providing trash and recycling pickup to residential and commercial customers in the greater Duluth/Superior, Wis. region.

Nordic’s trucks operate in the bitter cold of sub-zero winters as well as on humid summer days that can top out at over 90ºF. In addition, Lake Superior’s influence on the area’s weather patterns can create extreme temperature swings just miles from the lake, something Nordic’s trucks encounter regularly.

The company’s fleet runs 12 hours a day with frequent stops and redlined starts, all while hauling up to 22,000 lbs. of refuse

and navigating the seriously steep hills of Duluth.

As if the geographic challenges aren’t enough, perhaps the greatest strain these refuse haulers’ engines face is dumping the refuse. This action requires the engine to remain near or above redline throughout the process and shakes the truck enough to nearly lift the front tires off the ground. Nordic’s trucks dump their

contents twice daily, challenging the oil’s shear stability on a regular basis.

See the rest of this cost saving fleet study!

|

|

|---|

AMSOIL Diesel Oil Saves Money

Use of AMSOIL Synthetic 15W-40 Diesel and Marine Oil, along with oil analysis, has allowed Nordic Waste to extend its trucks’ oil drain intervals to nearly 1,000 hours – four times the length of service possible when using Shell Rotella T. Nordic’s trucks are well-protected and experience optimum fuel economy, so they stay out of the shop and on the road.

“We experience less downtime and have seen reductions in costs associated with engine overhauls and replacement parts,” said Johnson. Refuse haulers are very expensive, so maintaining spare trucks is not affordable for a small company. Operating with a minimal number of trucks requires maximum uptime to ensure

customers are serviced properly.

By delivering superior protection over extended drain intervals and improving engine reliability, AMSOIL Synthetic Diesel and Marine

Oil provides Nordic Waste consistent dependability and reduced maintenance (increased uptime). Increased uptime has helped Nordic Waste maintain an accurate schedule and provide excellent customer service – trucks are more readily available for routes when they aren’t in the shop for service. In addition to improving

the company’s operations, extended drain intervals save Nordic a considerable amount of money annually.