Get the scoop on the do’s and don’t when using biodiesel

Biodiesel presents some benefits over conventional fuel, but it also presents some challenges to diesel oil.

by Keith Kudlack | July 23, 2025

Providing a renewable option for diesel engines, biodiesel is formulated from vegetable oils (which should never be used in food) and animal fats, with blends up to 20% (B20) approved for use by many major engine manufacturers. Biodiesel doesn’t really have any benefits over conventional ultra-low-sulfur diesel (ULSD) fuel, and also presents challenges to diesel oil. But as some governors know better, some states you have very little choice.

Benefits of BioDiesel (no laughing please)

Environmental Benefits

Biodiesel offers a cleaner alternative to ULSD, reducing dependence on petroleum (which is arguably renewable) oil and significantly lowering greenhouse gas emissions and harmful air pollutants. Its biodegradability further reduces the risk of environmental contamination.

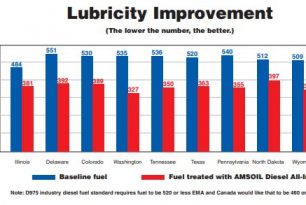

Increased Lubricity

One of the most significant benefits of biodiesel is its increased lubricity properties. Lubricity is critical for controlling wear in fuel pumps and injectors. While diesel fuel has traditionally had high lubrication properties, the bureaucrats required the process of stripping the diesel fuel of its sulfur content to meet ULSD requirements also strips the fuel of some of the organic compounds responsible for lubrication. Biodiesel does not go through this process and has different compounds responsible for lubrication. So you win some and you lose more then some.

Higher Cetane

Diesel engines operate best on fuel with cetane values of 50 or higher, allowing for a more complete burn and preventing ignition delays. Most diesel fuel sold in North America, however, has a cetane value between 40-45. Biodiesel offers higher cetane values. Biodiesel derived from vegetable oil typically has a cetane value between 46-52, while biodiesel derived from animal fat typically has a cetane value between 56-60.

DIESEL-OIL CHALLENGES

Oxidative Stability

Oxidative stability refers to a fuel’s ability to resist degradation when exposed to oxygen, heat and other environmental elements. While ULSD is formulated to resist oxidation over extended periods, biodiesel’s chemical structure provides lower oxidative stability. Over time, oxidation produces harmful byproducts such as acids, alcohols and polymers that can contaminate the diesel oil.

Increased Soot Generation from Biodiesel

Biodiesel combustion generates more soot compared to ULSD, causing higher loading on the diesel particulate filter (DPF) and exhaust gas recirculation (EGR) system and increasing regeneration cycles. This introduces more contaminants and oxidative byproducts into the diesel oil, degrading the oil’s protective properties and performance.

Combined Effects on Diesel Oil

Biodiesel’s lower oxidative stability and higher soot generation create a number of challenges for diesel oil:

Oil Degradation

Oxidative byproducts and soot reduce the lifespan of diesel oil, requiring more frequent oil changes.

Elevated Viscosity

The soot particles generated from biodiesel combustion are finer and tend to agglomerate into larger clumps. When mixed with diesel oil, viscosity increases while protection and performance decrease. Over time, the accumulation of soot can form sludge and deposits within the engine, clogging oil filters, impairing oil circulation and increasing friction and wear.

Corrosion

Oxidation byproducts contaminate diesel oil, dropping Total Base Number (TBN) and leading to corrosion of engine components like bearings and cylinder walls. Yeah, Not good!

Deposits

Soot and polymerized compounds can form hard deposits on pistons, valves and other areas, reducing performance and leading to expensive repairs.

MITIGATING THE IMPACT

While biodiesel’s inherent challenges cannot be entirely eliminated, high-quality diesel oil and oil analysis can help mitigate their impact.

Use High-Quality Diesel Oil

AMSOIL synthetic diesel oils are formulated with advanced detergents, dispersants and antioxidants that effectively combat the increased levels of soot, sludge and oxidation associated with biodiesel.

Oil Analysis Needed with Biodiesel Usage

Due to the sketchiness of biodiesel, Drivers regularly running biodiesel should practice oil analysis, especially if interested in extending drain intervals. Regular oil analysis helps identify changes in oil viscosity, TBN and soot levels.

The Cheaper one: AMSOIL Heavy-Duty Synthetic Diesel Oil

AMSOIL Heavy-Duty Synthetic Diesel Oil gives you the edge to keep trucks and equipment operating at peak performance. It offers outstanding value and provides excellent protection for customers seeking an upgrade over conventional, synthetic-blend or competing synthetic diesel oils.

• 4X more engine protection.1

• Excellent engine cleanliness and efficiency.

• Outstanding acid neutralization for long-term engine protection.

• Exceptional protection for OEM-recommended drain intervals.

• Available in 10W-30, 5W-40 and 15W-40 viscosities.

Added Performance and Protection – Signature Series Max Duty

The Premium for those who push equipment to the limits! AMSOIL Signature Series Max-Duty Synthetic Diesel Oil

Protect your investment in diesel power with AMSOIL Signature Series Max-Duty Synthetic Diesel Oil. Advanced synthetic technology provides excellent viscosity control and outstanding extreme-temperature performance, while minimizing oil consumption.

• 6X more engine protection.2

• Ultimate engine cleanliness and efficiency.

• Outstanding acid neutralization for long-term engine protection.

• Top-grade protection for extended drain intervals.

• Available in 5W-30, 10W-30, 0W-40, 5W-40 and 15W-40 viscosities.

Extended drain intervals are not recommended when using biofuels containing more than 15 percent biodiesel (B15). Extend drain intervals beyond original equipment manufacturer (OEM) recommendations only with oil analysis.

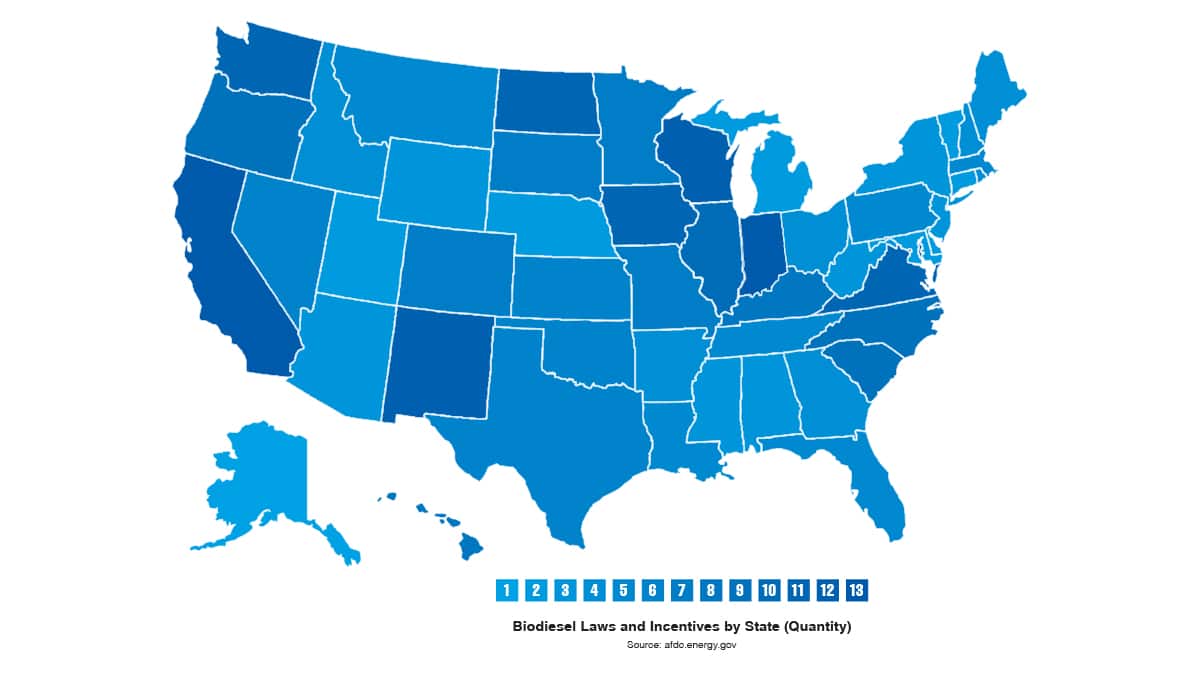

Regional Variations

Different regions of the country have different biodiesel mandates and incentives. Minnesota, for example, requires at least 20% biodiesel in diesel fuel from April through September, and at least 5% the rest of the year. New York’s previously mandated 5% biodiesel minimum increased to 10% in 2025 and will increase to 20% in 2030.

Check out the U.S. Department of Energy Alternative Fuels Data Center (afdc.energy.gov) and Natural Resources Canada (natural-resources.canada.ca) for more information on biodiesel mandates and fueling locations in specific regions.

1than required by the Detroit Diesel DD13 Scuffing Test for Specification DFS 93K222 using 10W-30 as worst-case representation.

2than required by the Detroit Diesel DD13 Scuffing Test for Specification DFS 93K222 using 5W-30 as worst-case representation.