Is an High Zinc Motor Oil really needed?

Thanks to Hugh Ashburn for asking this question on our Facebook page.

I assume when you say “older,” you mean a classic car or hot rod with a flat-tappet camshaft. Compared to their roller-cam counterparts, flat-tappet cams undergo sliding contact rather than rolling contact. This results in increased friction and, potentially, wear.

Added wear can affect valve lift and duration, which reduces engine power and efficiency. In extreme cases, increased pressure can remove material from the lobes and deposit it in the oil, where it circulates through the engine and causes damage. Break-in helps harden the metal so it’s more resilient to wear.

Here’s our resident expert, Len Groom, on this topic:

Want to learn more? Here’s what we’ll cover:

- What is high zinc motor oil?

- The role of piston rings

- Do you need a high-ZDDP oil?

What is high zinc motor oil?

Engine builders and gearheads typically use high-zinc and high-phosphorus (ZDDP) motor oil to offer extra protection for flat-tappet cams, lifters and other components during break-in. AMSOIL Break-In Oil, for example, contains 2,200 ppm zinc and 2,000 ppm phosphorus.

ZDDP anti-wear additives are heat-activated, meaning they provide wear protection in areas of increased friction. In this case, it’s at the cam lobe/tappet interface. The additives form a sacrificial layer on part surfaces, which absorbs contact and helps prevent cam and tappet wear. That way, your engine makes maximum power and lasts as designed.

The role of piston rings

Even though Hugh didn’t ask about it specifically, I should also mention the importance of seating the piston rings during break-in.

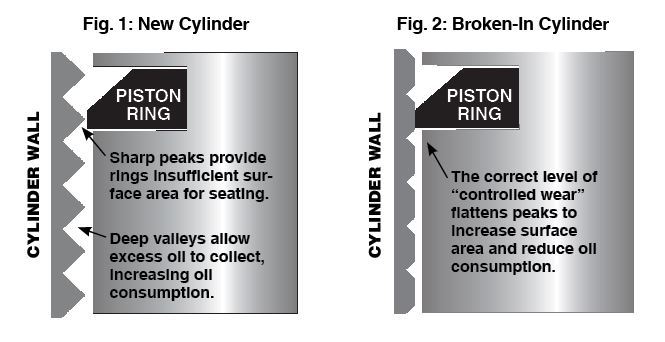

Although a new or freshly honed cylinder appears smooth to the naked eye, it actually contains microscopic peaks and valleys. If the valleys are too deep, they collect excess oil, which burns during combustion and leads to oil consumption.

The sharp peaks, meanwhile, provide insufficient area to allow the rings to seat tightly. That means highly pressurized combustion gases can blow past the rings and into the crankcase, reducing horsepower and contaminating the oil.

Breaking in the engine wears the cylinder-wall asperities, providing increased surface area for the rings to seat tightly. The result is maximum compression (i.e. power) and minimum oil consumption.

Do you need a high-ZDDP oil?

But, do you need to use a high-ZDDP oil in an older engine after break-in, which is typically about 500 miles?

Yes, if you want to maintain horsepower and promote longevity. And who doesn’t want that?

Even after the cam has seasoned, it’s still exposed to tremendous heat and pressure, especially in a heavily modified or racing engine. The constant barrage of pressure can rupture the oil film responsible for preventing wear, leading to metal-to-metal contact.

After break-in, we recommend using an oil with at least 1,000 ppm ZDDP in a flat-tappet engine. That way, you’re providing your expensive engine with maximum protection against wear and horsepower loss. AMSOIL Z-Rod Synthetic Motor Oil, our primary recommendation for classic cars and hot rods, contains more than 1,400 ppm zinc and more than 1,300 ppm phosphorus.

That’ll keep your classic car as happy as Hugh’s Thunderbird.